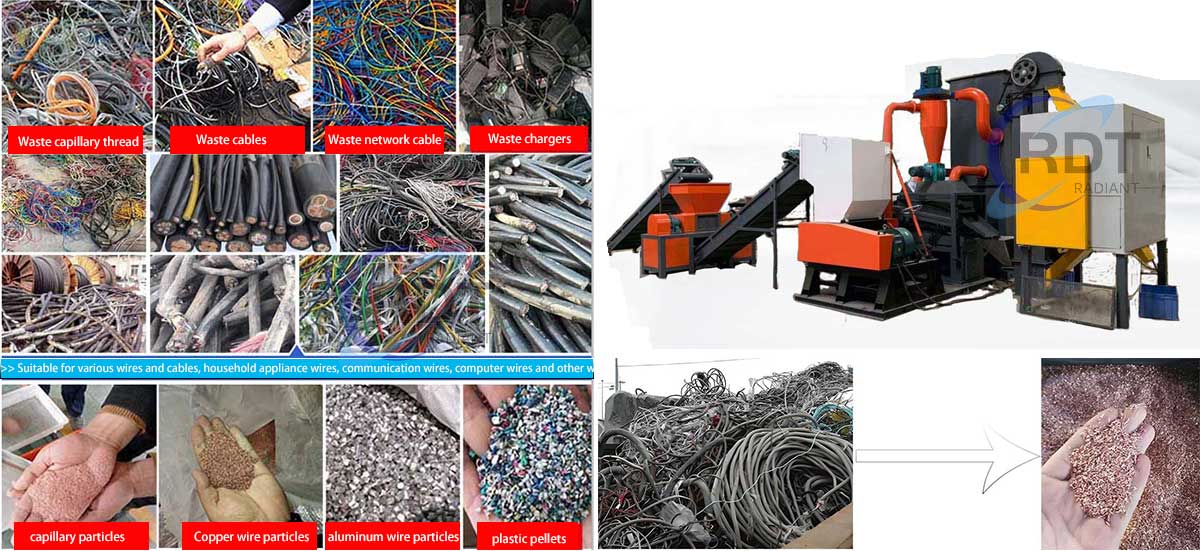

Machine de recyclage de câbles

La machine de recyclage de câbles est un dispositif mécanique spécialement utilisé pour traiter les déchets de câbles et en récupérer les matériaux utiles.. Cet équipement revêt une grande importance dans le domaine de la protection de l'environnement et du recyclage des ressources.. Il peut réduire efficacement la pollution des déchets de câbles pour l'environnement et réaliser la réutilisation des ressources.

Ⅰ、 Aperçu de l'équipement

La machine de recyclage de câbles décompose les déchets de câbles en différents composants, tels que les conducteurs métalliques tels que le cuivre et l'aluminium et les couches d'isolation en plastique, à travers une série de processus mécaniques et physiques. Ces matériaux peuvent être réutilisés pour produire de nouveaux câbles ou d'autres produits après traitement, réalisant ainsi le recyclage des ressources.

Ⅱ. Principe de fonctionnement

Le principe de fonctionnement de la machine de recyclage de câbles comprend généralement les étapes suivantes:

1. Écrasement: D'abord, les câbles de déchets sont introduits dans le concasseur pour un concassage grossier, briser les câbles en particules plus petites.

2. Séparation: Alors, les conducteurs métalliques et les couches d'isolation plastique sont efficacement séparés par des dispositifs de séparation spécifiques (comme les tamis vibrants, séparateurs magnétiques, etc.).

3. Recyclage: Le métal et le plastique séparés sont recyclés séparément. La pièce métallique peut être traitée ultérieurement pour préparer de nouveaux matériaux métalliques, et la partie en plastique peut être granulée ou recyclée.

Ⅲ、 Caractéristiques de l'équipement

1. Structure compacte, belle apparence, disposition raisonnable, et installation facile.

2. Le contrôle intelligent entièrement automatique permet à l'équipement d'être alimenté uniformément et de fonctionner intelligemment., facilitant l'opération, gain de temps et d'efforts, et assurer le fonctionnement stable de l'équipement.

3. Le concasseur adopte un type à double rouleau, basse vitesse, couple élevé, grande production, faible bruit, et opération simple.

4. Le broyeur, les équipements de tri et les équipements de dépoussiérage sont combinés sur une plate-forme, rendant l'équipement facile à déplacer et à transporter, et augmenter la flexibilité de l'équipement.

5. Le rotor du broyeur adopte un arbre de couteau alterné, ce qui rend le concasseur plus efficace, plus silencieux et plus stable.

6. Le taux de tri de l'équipement de tri par flux d'air est aussi élevé que plus de 99%.

7. Le système de retour permet de broyer deux fois les produits semi-finis, assurer la séparation des métaux et des non-métaux.

8. L'équipement de dépoussiérage en sac contrôle efficacement le débordement de poussière, et l'efficacité du dépoussiérage est aussi élevée que plus 99%.

Ⅴ、 Champ d'application

Fils de rebut qui ne conviennent pas au traitement par les machines à dénuder les fils, tels que divers fils et câbles, fils pour appareils électroménagers, fils de communication, fils d'ordinateur, etc..